Paragon 3000 Lithium Grease Lube-Shuttle®

SKU: 108500-1097

TRC's Paragon 3000 is now available in a Lube-Shuttle® Cartridge!

Multi-purpose, high-quality lithium grease (NLGI #2) offers extreme anti-wear protection under heavy loads, shock conditions, and normal loads. Passes a full 100 lb. Timken test. Best choice for high-heat applications.

These grease tubes work ONLY with threaded-tube-specific grease guns including the LockNLube LNL154 & LNL155.

- High-quality lithium grease (NLGI #2)

- Extreme anti-wear protection under heavy load and shock conditions and normal loads. Passes a full 100 lb. Timken OK test

- Wide temperature range. Pumps in hand-operated guns down to -5 degrees F. Dropping point of 630 degrees F

- Extreme stability and consistency. Does not soften like some greases allowing leakage away from the area where the grease is needed

- Moisture resistant. Resists being washed off by water and displaces water on metal surfaces. Pressure protection retained even in the presence of 20% water

- Adhesive and Cohesive. Resists squeezing out and thinning under severe loads. Adhesive characteristics develop a dust shield to protect bearings

- Multi-purpose grease ideal for a wide range of applications covering heat, moisture, load, impact and stability questions

LockNLube is a Texas Refinery Corp Authorized Distributor

Free U.S. Shipping on Orders $74+

Offers Outstanding Extreme Pressure Protection

PARAGON® 3000 offers tremendous anti-wear protection. PARAGON® 3000 passes a full 100 lb. Timken OK test. Equipment subjected to heavy load and shock loading function at peak efficiency. Unlike many High Timken Value greases, this product offers superior protection throughout the entire range of load. Often special greases manufactured to offer protection under incredibly high loads do not protect from wear when loads are more normal. PARAGON® 3000 offers exceptional anti-wear protection – – regardless of the load – – including a 100 lb. Timken OK load.

PARAGON® 3000 Protects Against Hydrogen Sulfide

TRC now incorporates an H2S (Hydrogen Sulfide) Scavenger in PARAGON® 3000 for additional protection in applications where this corrosive gas is found. Hydrogen sulfide is often associated with the fracking and drilling industry, mining operations, sewer gas, swamp gas, water treatment facilities, animal waste, garbage dumps, paper and textile mills, facilities that handle used/waste oil and many other petroleum and industrial areas. Customers working in these tough environments can be assured they have the ultimate protection with Paragon 3000!

A Very Stable Grease With A Long Working Life

PARAGON® 3000 is an extremely stable grease. This is an indication of its long life in actual working conditions. Many greases change significantly in consistency when in actual operation, often thinning considerably or thickening. PARAGON® 3000 shows very little change in its worked penetration from the 60 round-trip strokes compared to the 10,000 round-trip strokes in a standard grease worker. Even more significant, PARAGON® 3000 changes little even in the 100,000 double stroke test. After 100,000 strokes PARAGON® 3000 changes from a penetration of 280 to 274 in its consistency. Most greases in the 100,000 double stroke test change considerably in their consistency. Some of them become too soft, allowing leakage away from the area where the grease is needed. Other greases become too hard, indicating they may not feed adequately into areas to be lubricated. PARAGON® 3000 is extraordinarily constant and stable, thus providing the ultimate in protection.

Highly Water Resistant

Texas Refinery Corp’s PARAGON® 3000 is resistant to moisture. This grease can be used in areas where ordinary greases would simply be washed away. PARAGON® 3000 resists being washed off by water and, in fact, displaces water on metal surfaces, keeping those surfaces free from rusting, pitting and corrosion. Extreme pressure protection (100 lb. Timken OK Load), is retained even in the presence of 20% water. This is remarkable for any lubricant – – but not for PARAGON® 3000. This extreme water resistance provides the answer to many current industrial equipment problems. One example where PARAGON® 3000 could be used is in paper mills where heat, water and extreme conditions are present. The more conditions are extreme, the greater PARAGON® 3000 performs.

Handles Impact And Prevents Wear

PARAGON® 3000 contains specially developed high impact resistant supplements. These supplements enable PARAGON® 3000 to resist severe and continuous impact. This characteristic enables this grease to prevent wear, ensure longer service life and provide a new dimension in downtime protection. PARAGON® 3000 resists squeezing out and thinning under severe loads, thereby preventing metal to metal contact. The adhesive and cohesive characteristics make this grease suited for many demanding jobs. The adhesive characteristics also help develop a dust shield to prevent contaminates from getting into bearings.

A Unique Grease For Many Different Applications

PARAGON® 3000 is the only grease made using a unique combination of thickeners and additives. PARAGON® 3000 is ideal for a wide range of applications covering heat, moisture, load, impact and stability questions. It is a true multi-purpose product.

Has A Wide Operating Temperature Range

PARAGON® 3000 offers extreme temperature protection. Most greases have dropping points between 290 and 390 degrees F. PARAGON® 3000 has a dropping point of 630 degrees F.

- Shipping options are available at checkout

- All of our orders ship out of either our Illinois or New Hampshire warehouse within 3 business days.

- Shipping carrier varies by size and weight of the package.

- LockNLube's shipping department operates Monday through Friday, 8 am to 2 pm EST except for holidays.

- Reviews

- Questions

- grease

- mess

- delivery

- Shipping

- prime

- second

- mistakes

- weight

- trouble

- bottom

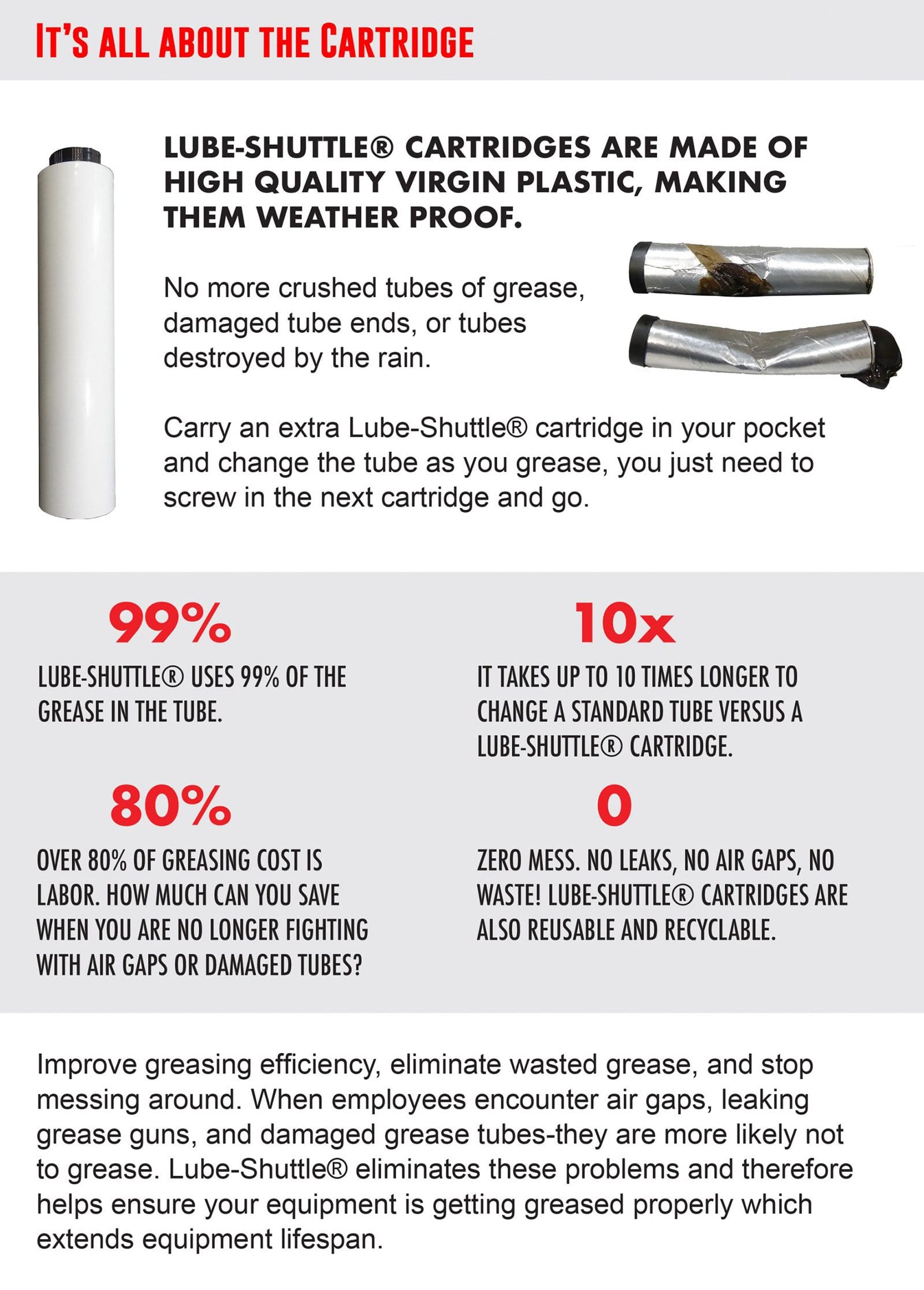

No fuss No mess

Replacing the Lube-Shuttle is very easy to do without getting grease everywhere and on me!

Great Lube System

Easy to use, no mess. I absolutely love this purchase!

Excellent product

Best grease gun I have ever used. I've used dozens and this is by far the best one I have ever had.